Home List your patent My account Help Support us

Turbine blades with the effect of recovery..fuel economy.

[Category : - RENEWABLE ENERGY- Motors- Pumps]

[Viewed 2379 times]

accounted for 5 years from 30.12.2019 to 29.12.2020 Hello!rnMy name is Nikolai Shokhin.I am inventor and oner of the patent nomber:170363 the picture here Link

.Russian Federation is protected efficient turbine blades and aircraft propeller.Now ended the process of patenting innovations of my idea is the energy of the oncoming air flow due to the effect of the sail.This effect is created by the special shape of the blade.Blade has a special part.This area I call the sail area or sail part of blade.Shape of my blade differs from conventional turbine blade or screw.The aerial blades may be of different shape but always present part of the sail which allows you to offset part of the costs for the rotation of the screw shaft or the turbine.One of the options it s shape.Be used in this invention may in airspace and water screws and turbines of aircraft and turbines and screws pumps. One of the implemented ideas is the movement of a sailing vessel at an angle to the wind.Another example can be found in nature.In viewing the slow motion of the wings of birds and insects. The Calibri, you just and dragonflies.rnrnThere is the idea of increasing the efficiency of the engine in a simple way but bringing efficiency to impulse engines.Thanks to simple and inexpensive revision of existing ones. For all inquiries and information in inglish please contact. The improved shape of the jet engine turbine blade, patented by me, reduces noise and increases efficiency.For final advice, contact me to create a complete picture and all the factors that determine performance gains. 89296563340. Nikolai Shokhin.PATENT NUMBER 170363 Russian Federation //////////////////////[Use the button below to contact me] ///////// +79296563340 //// aplication number 2015156830.//////

(12) DESCRIPTION OF USEFUL MODEL TO THE PATENT

Status:

Custom duties: valid (last change of the status: 27.04.2017)

it is considered for 1 year from 29.12.2015 till 29.12.2016

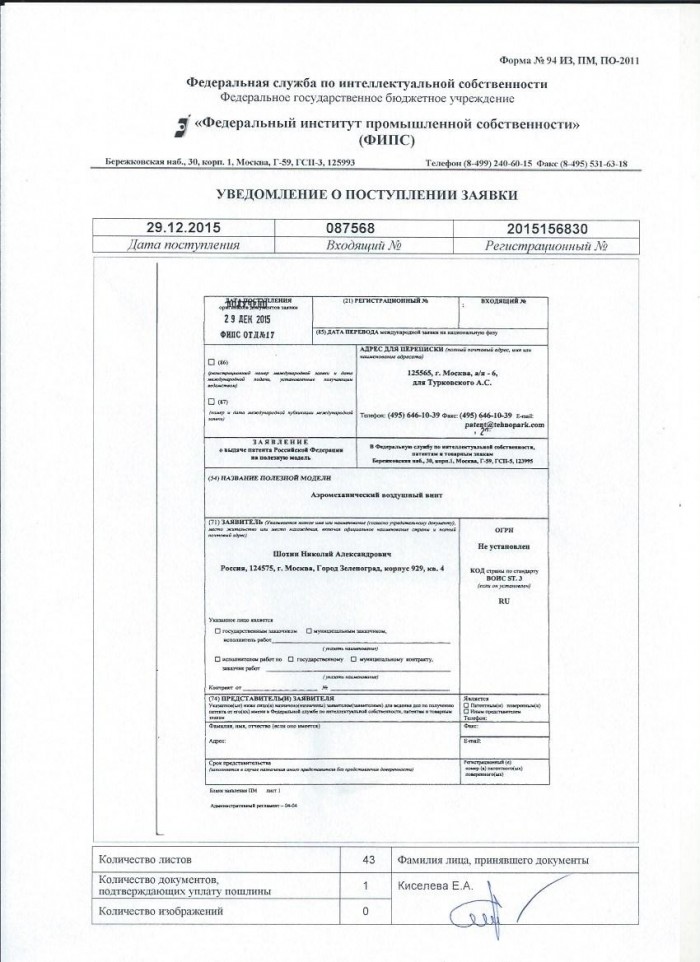

(21)(22) Application: 2015156830, 29.12.2015

(24) Starting date of patent:

29.12.2015

Priority (-ies):

(22) Filing date: 29.12.2015

(45) Published: 24.04.2017 Bulletin No.12

(56) List of documents cited in the search report: US 20070217917 A1, 20.09.2007. US 4519746 A, 28.05.1985. RU 2465173 C1, 27.10.2012. US 2982361 A, 02.05.1961.

Address for correspondence:

[Use the button below to contact me]

+7 929 656 33 40

Shokhin Nikolay.

(72) Author (s):

NikolajAleksandrovichShohin(RU)

(73) Patent holder (s):

NikolajAleksandrovichShohin(RU)

(54) Aerodynamic propeller

(57) Abstract:

The declared useful model belongs to the aircraft equipment, in particular to the device of the pulling and lifting propellers of planes including unmanned aerial vehicles, and extralight planes.

The purpose of the declared useful model is achievement of such technical result as increase in efficiency of operation of the aerodynamic propeller.

?

This goal is achieved in the following way: aerodynamic propeller containing the hub installed on the shaft fixed thereto at an angle to the plane of rotation at least two blades, and each blade has a front and rear surface relative to the oncoming air stream and side edges, wherein the surface of a blade have different curvatures, so that the rear surface is convex and the front surface is concave and the side edge parts of the surface curvature of each blade, the radius of curvature of the front surface exceeds the radius of curvature of the rear surface.

The declared aerodynamic propeller is the reliable and simple device with high efficiency. It is suitable for use as the pulling and lifting propellers of planes including unmanned aerial vehicles, and extralight planes.

Fig. 4

The declared useful model belongs to the aircraft equipment, in particular to the device of the pulling and lifting propellers of planes including unmanned aerial vehicles, and extralight planes.

The known aerodynamic propeller (patent RF 2349504, published on 20.03.2009) with controllable pitch of blades comprising blades connected to the propeller shaft with the help of elastic bending and torsion of torsional bars, the elements of pitch control of each blade. Each of the torsion bars at all elastic segment between the blade and the shaft or in the area along the length of this area experiencing mainly deformation of the torsion, made in the form of the beam consisting of a set of longitudinally spaced force elements open profile with a high strength material, connected by an elastic filler material with low shearing resistance, and the fittings on the ends of the torsional bar

?

or torsion segment - in the area of the curve, at the connection of torsional bar with the blade, shaft, intermediate parts, at the joints areas of the torsion and bending of one torsion bar or torsion bars between them, the power components are connected by a tough material with high strength. A disadvantage of the known design is the low efficiency.

Also the known aerodynamic propeller (patent RF 2465173 published on 27.10.2012), consisting of blades connected to the hub mounted on the shaft, and each blade is connected to the shaft of the screw with the elastic torsional element. The elastic torsional element is the root transition segment of the blade, thus setting the blades at a specified angle is provided with the shift of the center of the blade pressure relative to its axis elastic torsional root transitional site in the plane of rotation of the screw.

It is possible to refer low efficiency to the disadvantages of the declared decision.

The closest analogue to the declared design, is the rotary device for fluids (patent US 20070217917 published on 20.09.2007) comprising at least two blades comprising a large number of elementary profiles having a base end portion, the front and rear surfaces, the front and rear edges. At least two blades at the same distance attached to the hub containing the means of joining to the rotating shaft.

It is also possible to refer low efficiency to disadvantages of the declared decision.

The purpose of the declared useful model is to eliminate this disadvantage for the achievement of such technical result as improving the efficiency of the aerodynamic propeller.

This goal is achieved in the following way:

aerodynamic propeller containing the hub installed on the shaft fixed thereto at an angle to the plane of rotation at least two blades, and each blade has a front and rear surface relative to the oncoming air stream and side edges, wherein the surface of a blade have different curvatures, so that the rear surface is convex and the front surface is concave and the side edge parts of the surface curvature of each blade, the radius of curvature of the front surface exceeds the radius of curvature of the rear surface.

The aerodynamic propeller, in particular, can be characterized by the fact that blades are executed monolithic of the single massif of material.

The aerodynamic propeller, in particular, can be characterized by the fact that blades are executed from the massif of the tree.

The aerodynamic propeller, in particular, can be characterized by the fact that blades are executed from metal casting.

The aerodynamic propeller, in particular, can be characterized by the fact that blades are executed hollow with internal longerons and ribs.

Aerodynamic propeller front view is depicted in Fig. 1, Fig. 2 shows a midline incision of the blade, Fig. 3 shows a portion of the blade, indicating the radii of curvature of its surfaces, Fig. 4 shows a section of a hollow blade with a cutout showing the longerons and ribs of its construction, where the numbers indicate the following:

1 - hub.

2 - shaft axis.

3 - blade.

4 - front surface of the blade.

5 - rear surface of the blade.

6 - direction of the incoming air

7 - side edges of the blade.

?

8 - radius of curvature of the front surface of the blade (R1).

9 - radius of curvature of the rear surface of the blade (R2).

10 - longerons.

11 - ribs.

The aerodynamic propeller presented on figures is arranged as follows.

Blades 3 are fixed on the shaft axis 2 by means of the hub 1. The blade 3, in turn, consists of longerons 10 and ribs 11.

The aerodynamic propeller presented on figures operates as follows.

The engine (not shown in fig.) through the shaft axis 2 transmits the rotary motion of the blades 3 mounted on the axis using the hub 1. The blades 3 thus making a rotational movement in a plane perpendicular to the axis of the shaft. During the aircraft flight on the front surface of the blade 4 there is incursion of the air flow in the direction 6. Incoming air is further spins the screw, thereby reducing the power requirements for the engine of the flying device. In addition, when the radius of curvature of the front surface of the blade (R1) 8 and the radius of curvature of the rear surface of the blade (R2) 9, so that R1>R2, will increase outcome effectiveness. Because the declared configuration of the blades is the incoming flow at the optimum for a particular propeller cruising speed according to the additional rotation of the blades, providing the excess of the useful component of force that pushes the device forward over the resistance force that creates this stream.

Side edges of the blade 7 is divided by the surface curvature of the front 4 and rear surfaces of the blade 5. Thereby efficiency of the declared aerodynamic propeller increases including due to that fact that the stream behind a rear edge of the blade is as close as possible to laminar in front of the screw and does not create harmful turbulences behind it.

The blades 3 themselves can be made from a single massif of material such as wood or metal castings. Or it may be hollow with the design of the longerons 10 and the ribs 11.

The use of blades with a concave front surface and convex rear surface, so that the radius of curvature of the front surface exceeds the radius of curvature of the rear surface and the side edge parts of the surface curvature of each blade allows to achieve the claimed technical result, namely improving the effectiveness of aerodynamic propeller.

Industrial applicability.

The declared aerodynamic propeller is a reliable and simple device with high efficiency. It is suitable for use as the pulling and lifting screws of planes, including unmanned aerial vehicles, and extralight aircraft.

Formula of useful model

1. Aerodynamic propeller containing the hub installed on the shaft fixed thereto at an angle to the plane of rotation at least two blades, and each blade has a front and rear surface relative to the oncoming air stream and side edges, wherein the surface of a blade have different curvatures, so that the rear surface is convex and the front surface is concave and the side edge parts of the surface curvature of each blade, the radius of curvature of the front surface exceeds the radius of curvature of the rear surface.

2. The aerodynamic propeller as claimed in claim 1 characterized in that the blades are executed monolithic of the single massif of material.

?

3. The aerodynamic propeller as claimed in claim 1 characterized in that the blades are executed from the massif of the tree.

4. The aerodynamic propeller as claimed in claim 1 characterized in that the blades are executed from metal casting.

5. The aerodynamic propeller as claimed in claim 1 characterized in that the blades are executed hollow with internal longerons and ribs.

?

The improved shape of the jet engine turbine blade, patented by me, reduces noise and increases efficiency.For final advice, contact me to create a complete picture and all the factors that determine performance gains. 89296563340. Nikolai Shokhin.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-13 19:03:37, Patent Auction Time.

Patent publications:

Patent publications: RU 170363

RU 170363 Great invention

Great invention