Home List your patent My account Help Support us

PIPE INSPECTION ROBOT

[Category : - ELECTRONICS- MECHANICAL ENGINEERING- SOFTWARES]

[Viewed 3300 times]

Robotics is one of the fastest growing engineering fields of today. Robots are designed to remove the human factor from labor intensive or dangerous work and also to act in inaccessible

environment.

The use of robots is more common today than ever before and it is no longer exclusively used by the heavy production industries.

One of the main concern affecting all buildings and industries is the maintenance required.

Thisimplies wasting of time and money necessary to prevent from future damages and to fix those already happened.

In particular great problems are associated with the maintenance of pipes.

Various pipe linesusually become old after several years, such as steel pipes in factories, steel pipes used for water pipe and gas pipe, ceramic pipes, concrete pipes, and plastic pipes. The pipelines are the major tools for the transportation of drinkable water, effluent water, fuel oils and gas. A lot of troubles caused by piping networks aging, corrosion, cracks, and mechanical damages are possible.

The inspection of pipes may be relevant for improving security and efficiency in industrial plants.

These specific operations as inspection, maintenance, cleaning etc. are expensive, thus the application of the robots appears to be one of the most attractive solutions.

It is possible to detect cracks or corrosion thinning in plumbing with various methods of non destructive testing, such as eddy-current or ultrasonic sensors, but these require access to the

outside of the pipes; difficult and costly in many situations, such as long, buried lengths.

Furthermore, this does not address the problem of clogging or fouling. In many such applications,

an internal inspection solution may be preferable.

If a robot were designed to travel the length of the pipe and conduct such inspections, it might have

other uses as well. For instance, it could carry a cleaning mechanism or manipulators to remove

foreign objects. It could pull electrical or communications cables through conduits. Such a machine

has potential as a life-saving tool also: when buildings collapse, due to earthquakes or other disasters,

the internal pipe network may still be navigable for a pipe crawling robot, which could carry video cameras or microphones to locate signs of humans trapped below.

In order to inspect and repair these pipes, a flexible automatic inspection robot is needed, besides,

for controlling the inspection robot and transmitting the collected data to terminal which is located at pipe inlet,

wireless communication system for life maintenance is applied. An in-pipe inspection robot has been designed that can: deal with many kinds of pipes with various diameters such as plastic pipes or metallic pipes, Save comprehensive investment, improve workefficiency, more accurate detection and easy to operate.With this system, defects or troubles inside pipe could be inspected, and also image information inside pipe can be transmitted.

1.2 Purpose and objectives of the Project

This project is intended to produce a robot capable of traveling through a network of pipes for the

purpose of inspection from inside.

OBJECTIVES:

Development of an automated system for in-pipe inspection, which can inspect the pipe

network from inside the pipe and traverse inside the pipe with forward and backward

motion using wireless communication system.

Provide inspection without loss of equipment.

Remove humans from potentially hazardous work situations.

Reduce equipment and plant downtime.

Improve maintenance and inspection procedure thorough better coverage and

documentation

1.3 Constraints on the robot

Design of the inspection robot depends on two main critical factors: size and shape of the pipeline.

It will weigh strongly on the manoeuvrability of robot and its dimensions. An ideal robot should:

1. Drive through a pipe that can change its diameter along his pattern;

2. Have sufficient traction to move and to carry out tasks as measurements or clogging detection in a slippery and not plane surface as a pipe.

3. be robust and reliable

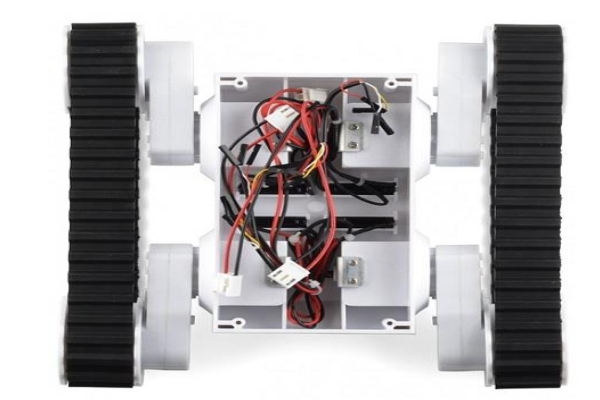

1.4 Construction and working of pipe inspection robot An in-pipe inspection robot composed of body, four wheels system, it is able to move freely inside pipes of different diameters. A CCTV camera is installed on front part of the system to dvisual inspection of pipe.

The robot mainly employs plastics as structural material. Each wheel have of a DC motor, four independent motors, each with an optical quadrature encoder and gearbox. The entire gearbox assembly can be rotated at 5 degree increments for different clearance configurations. You can even replace the tank treads with traditional wheels.

For inspection, robot is put into pipe. When electric supply starts, the robot moves through the pipe with distance measurement. The CCTV camera does visual inspection of pipe and it gives an image of robot path in each crack detection cycle and it gives wireless data to computer. In this way we get size and location of crack from starting point on display screen of computer.

This invention is available for sale or license. Patent pending.

Patent publications:

Patent publications:No publication

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-04 15:52:11, Patent Auction Time.

Great invention

Great invention