Home List your patent My account Help Support us

3G SUPERCONDUCTING ELECTRIC WIRE

[Category : - CHEMISTRY- ELECTRICITY & LIGHTING- RENEWABLE ENERGY]

[Viewed 5275 times]

Applications of 3G High Temperature Superconducting wires can 2 – 5x decrease cost, weight, diameter (size), and heat losses of electric cables, motors and transformers.

The US Department of Energy estimated the worldwide market for reliable and inexpensive HTS electric wire as $200 billion/year.

33 years ago, two Nobel Prize winners discovered High Temperature Superconductor (HTS) ceramic crystals that at easily achievable cryogenic temp-re of cheap liquid nitrogen (LN) coolant transmit without heat losses enormous amount of electric current. Meanwhile, until now developed 1G and 2G HTS electric wires are not yet on the open market and cannot compete with traditional copper wire due to high capital and production costs and usability, quality and reliability drawbacks.

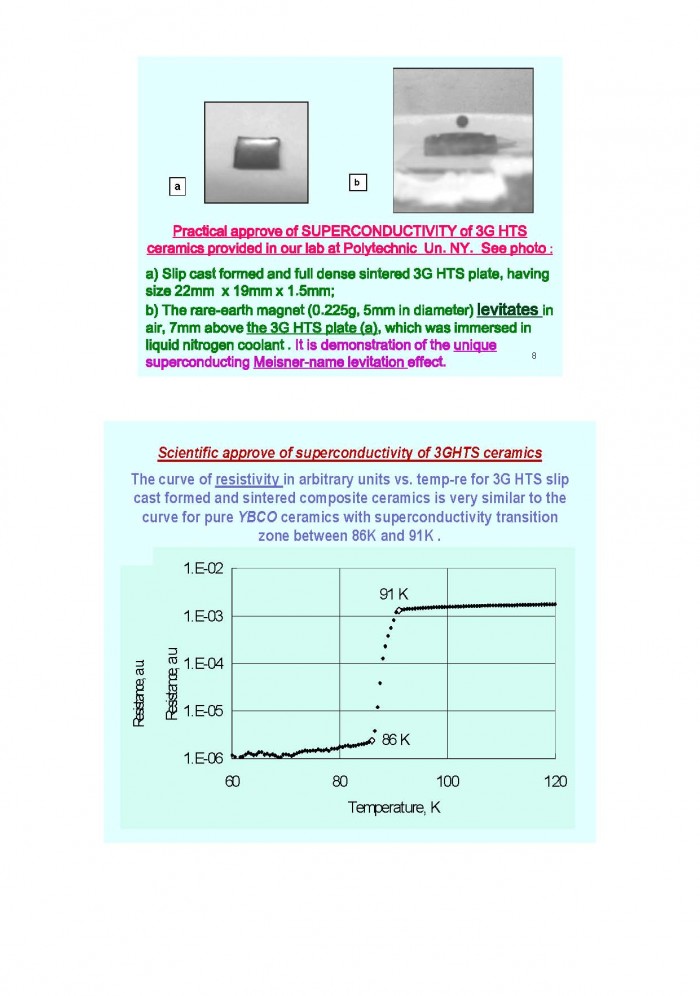

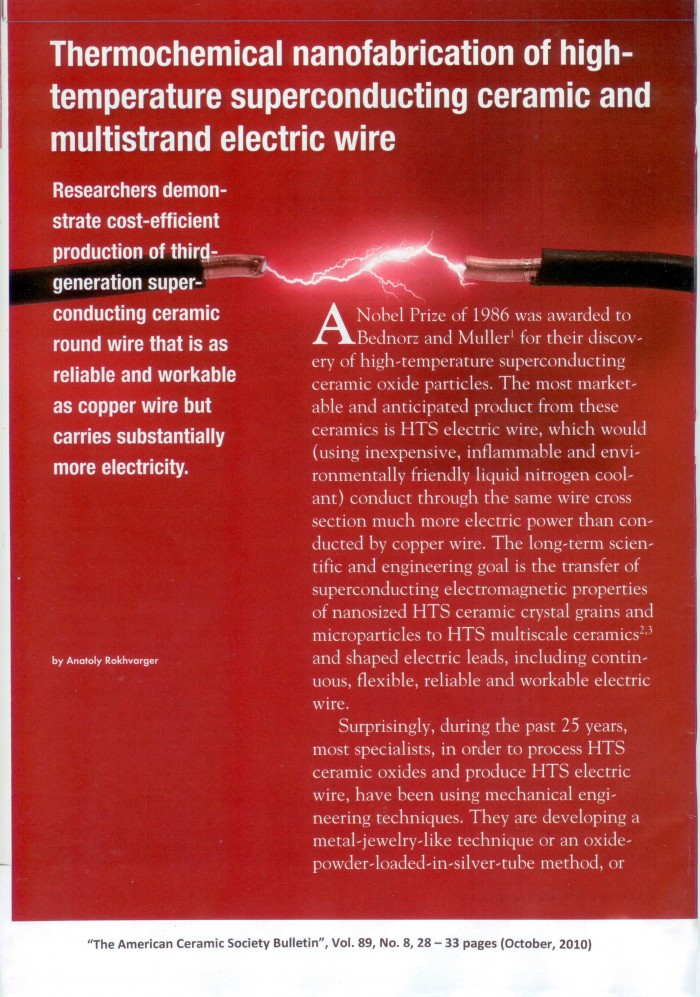

At Polytechnic School of Engineering of New York University we provided adhesion coating of NiCr-metal strand substrates by market available HTS ceramic powder, and then we provided 10-steps thermo-chemical processing.

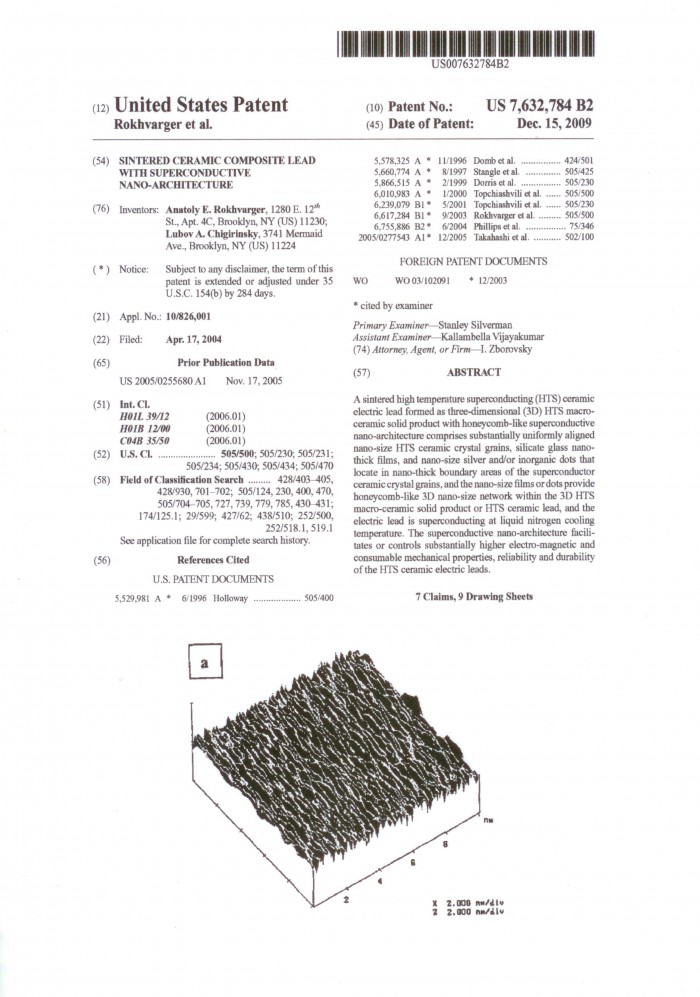

We invented and in lab approved: 1) material formulation for new HTS composite ceramics; 2) a method of thermo-chemical nanofabrication of the superconducting ceramic nano-architecture; 3) a method of production of substrate coated HTS strands; 4) advanced Electrical Engineering material, which is 3G HTS wire strands and 5) a method of continuous manufacturing of 3G HTS multi-strand electric wire.

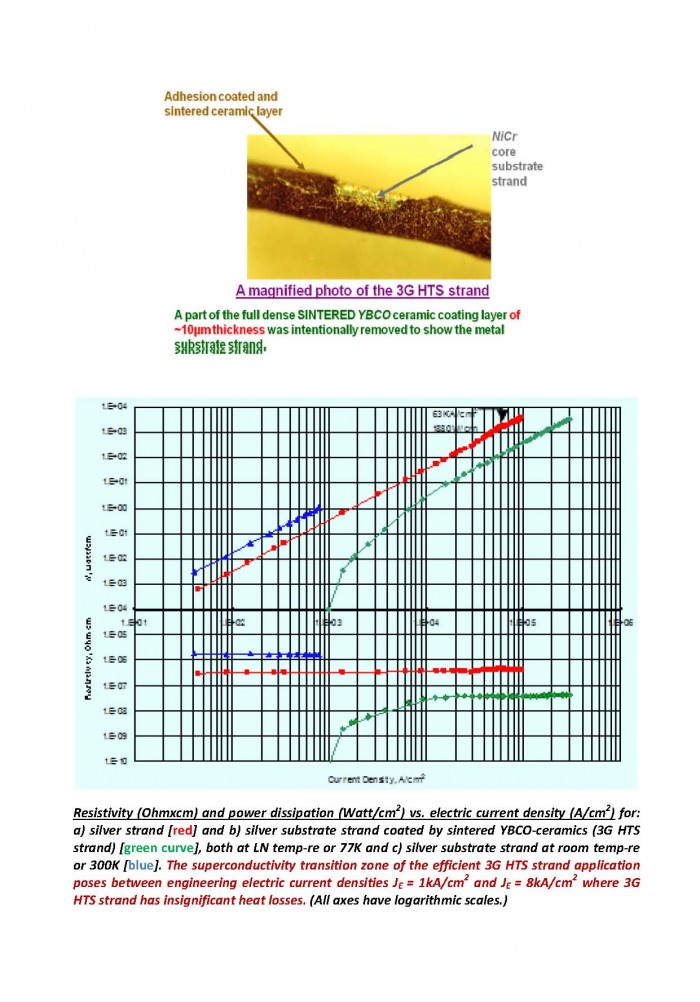

At room temp-re, 3G HTS wire strands work as metal conductor, with resistance, which less than resistance of the best metal conductor - silver. At room temp-re 3G HTS strands can carry with insignificant heat losses up to J = 1 kA/cm2. This makes 3G HTS wire competitive with traditional copper wire, which usually works at J = 0.2 kA/cm2.

At LN temperature there are three zones for practical application of 3G HTS wire:

1) Superconducting zone with zero heat losses in the current range less than 1kA/cm2

2) Especially efficient hybrid conducting/superconducting transition zone with insignificant heat & power losses in the range of the applied current density 1 – 10 kA/cm2

3) Conducting zone at the applied current >10kA/cm2 where 3G HTS strands have 10x less resistance than the best metal conductor, silver, and heat grows in correspondence with an increase of the current.

Our US Patent #7,632,784 and knowhow cover our previous US patents ## 6,617,284, 6,239,079, 6,010,983 and approved: 1) by 3 groups of experts, 2) in 14 peer reviewed journal publications, and 3) by 15 presentations at the American Ceramic, Chemical Engineering, Mechanical Engineering, Materials Research, NSTI Nano-Tech and New Jersey Technical Council society meetings.

We produced 10 micron thick full dense sintered and therefore integer and uniform stone-like superconducting ceramic coating layer of strands with total dia. = 0.06mm. These strands (named as 3G HTS strands) are flexible and reliable as copper wire.

At easy achievable liquid nitrogen (LN) temp-re 3G HTS strands can carry with insignificant heat losses J=10kA/cm2 while copper wire at room temp-re transmits J=0.2kA/cm2. Obviously, LN cooled 3G HTS strands with dia. = 0.06mm can substitute electric copper strands with dia. = 0.6mm that work at room temp-re.

Financial information

The 3G HTS strands with dia. = 0.06mm should cost $0.004 per meter while the copper strands with dia. = 0.6mm cost $0.014 per meter. Therefore, if a plant owner would assigns for 3G HTS strands with dia. = 0.06mm the same price $0.014/meter, a profit will be $0.01/meter.

The fully mechanized typical technological line using split electric furnace would cost $2 mill and produce 100,000 km/year-strands that should be woven in to multi-strand electric wire or cable with required electrical current carrying capacities. It brings plant owners $1mill/year pre-tax profit at ROI = 50%. The plant with, for example, 20 typical production lines will bring $20 mill/year pre-tax profit.

Taking in account the tremendously large $200 billion/year market and billion dollars that were previously spent for development of unsuccessful 1G and 2G HTS wires, we propose especially attractive licensing opportunities.

Right now a cost of license of the US patent set, knowhow and their feasibility approve should be at least $0.4mln plus royalties and some percentage from possible technology selling or relicensing costs.

If someone invests $2mln or $6mln, there would be developed either a prototype or industrial technological line for continuous production “substrate reels” - to - “3G HTS strand reels” and multi-strand 3G HTS wire and cable. These would allow licensing of the 3G HTS nanotechnology and multi-strand conducting-superconducting 3G HTS electric round wire for, correspondingly, $10mln - $15mln or $80mln - $100mln.

Applications of SCC (or 3G HTS) wires at both LN or room temperatures can 2 – 5x decrease cost, weight, diameter (size), and heat losses of electric cables, motors and transformers. The US Department of Energy estimated the worldwide market for reliable HTS electric wire as $200bill/year.

Additional Advantages of 3G HTS Wire APPLICATIONS include:

1). In contrast with a tape form wire, round form of 3G HTS strands and multi-strand wire are usable and efficient for cables as well as for coils of electric motors, transformers. 2). Open surface contacts of round 3G HTS strands allow compensation of the breaches of superconductivity in neighbor strands, which assure reliability of the multi-strand wire or cable. 3.) Surface contacts allow splitting connection/joining of pieces of multi-strand wires or cables. 4.) Round form of 3G HTS wires and cables makes easier design of their cooling systems. 5). The use of 3G HTS cables with their cooling jackets 5x decreases width of high power cable underground tranches within towns or cities.

6). Permanent reliability of 3G HTS multi-strand wire and its Electrical Engineering applications. 7.) Nonflammable LN coolant substitutes flammable oil in electric motors and transformers.

Invented 3G HTS multi-strand electric wire can be used for::

1) Electric motors, transformers and generator rotors with 5x reduced costs, weights and sizes, 2) Electric cables of any carrying capacity with 5x reduced costs, weights and diameters; 3) Cost-effective electric grids; 4) Electromagnetic propulsion jet engines for aircrafts and high-speed ships; 5) Supercomputers and a supercollider; 6) Current limiters on the electric systems and grids; 7) Superconducting magnetic energy storage (SMES) systems for: a) an assurance of the electric grids and b) fast recharging of electric cars to support or substitute large batteries;

Invented nanotechnology and HTS composite material can be used for::

1) 3G HTS ceramic coating metal surfaces of any configuration for antennas 2) Pellets and other bulk leads for rails of magnetic levitation (MagLev) high-speed trains; 3) Gyroscopes and other devices employing unique levitation effect; 4) The spectrum of electronic precise systems and devices using signals filtration or definition

Broad use of 3G HTS wire and invented HTS material will result in saving 10% power, which now just heat Environment. For the US it is equal to power capacity of 100 working now in the US atomic (nuclear) power stations.

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-15 5:08:16, Patent Auction Time.

Patent publications:

Patent publications: US 7632784

US 7632784 Great invention

Great invention