Home

List your patent

My account

Help

Support us

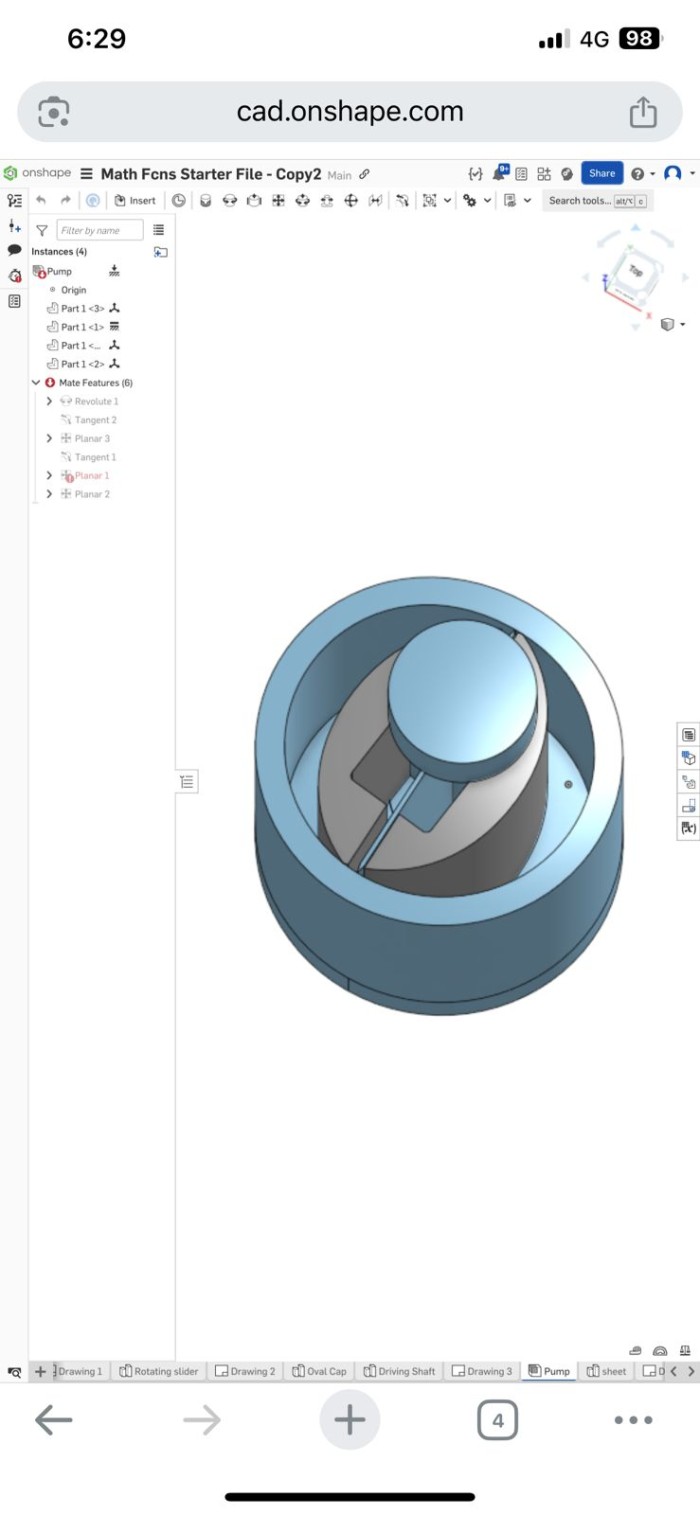

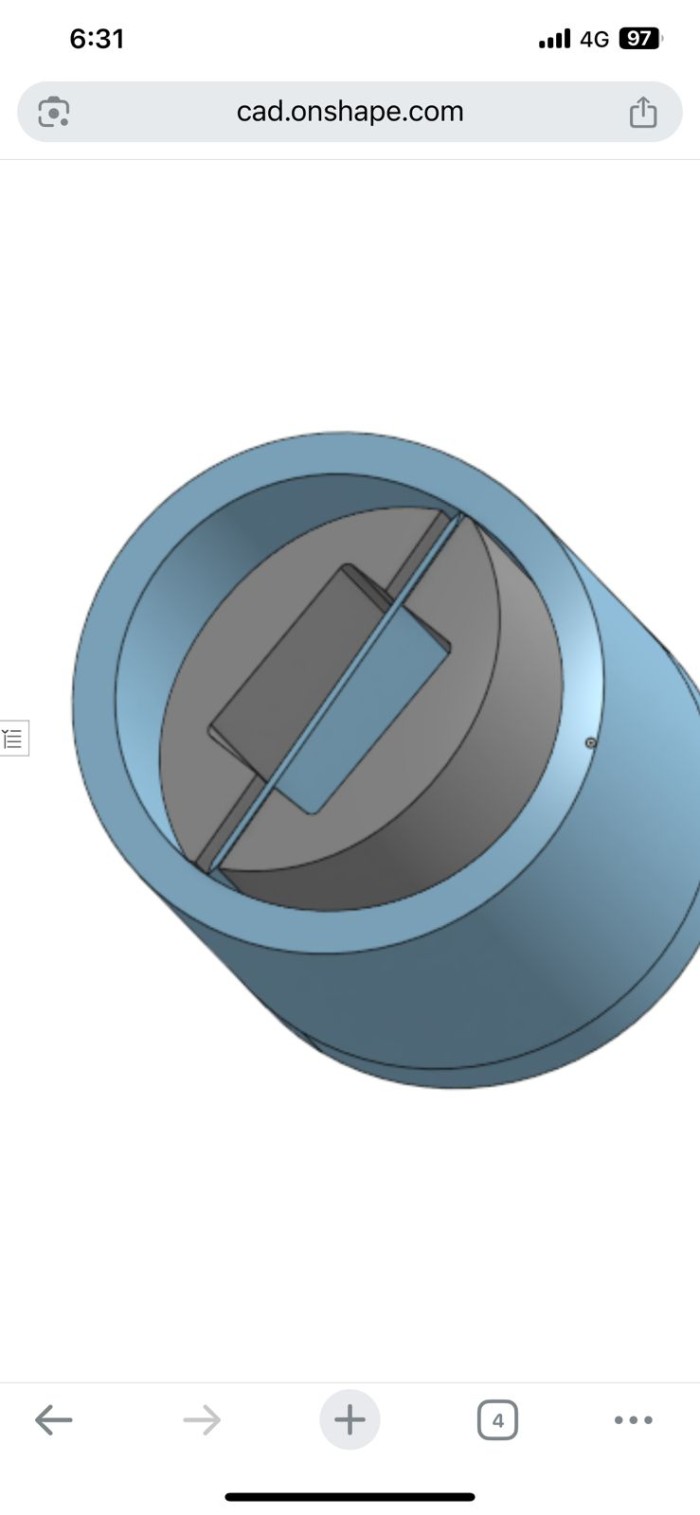

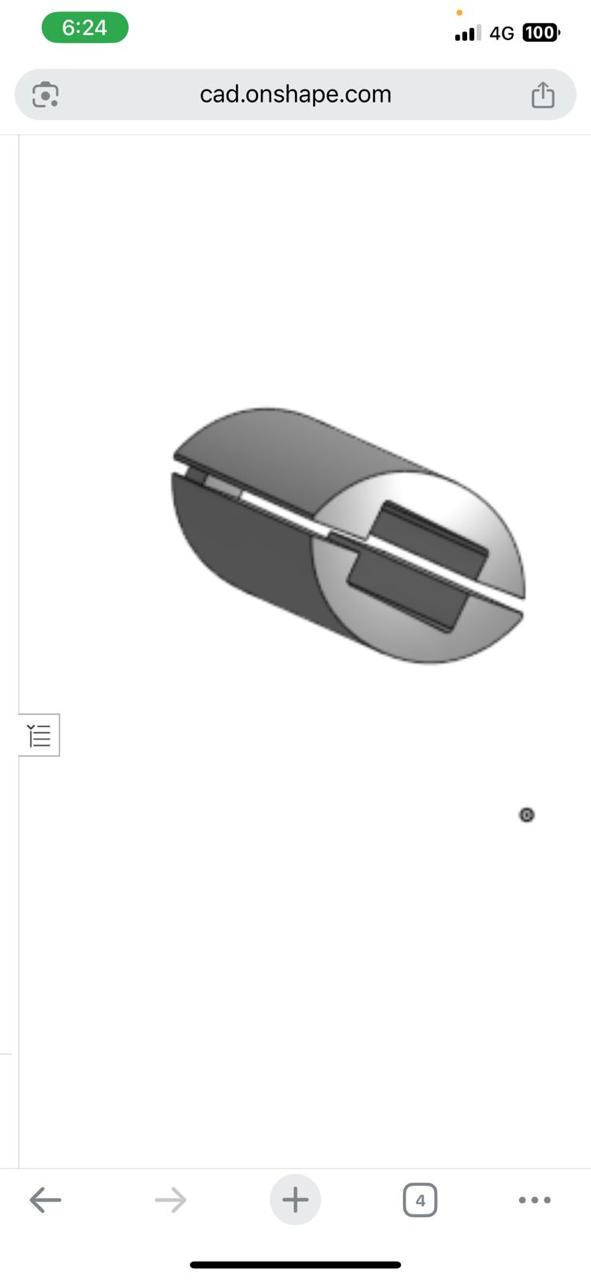

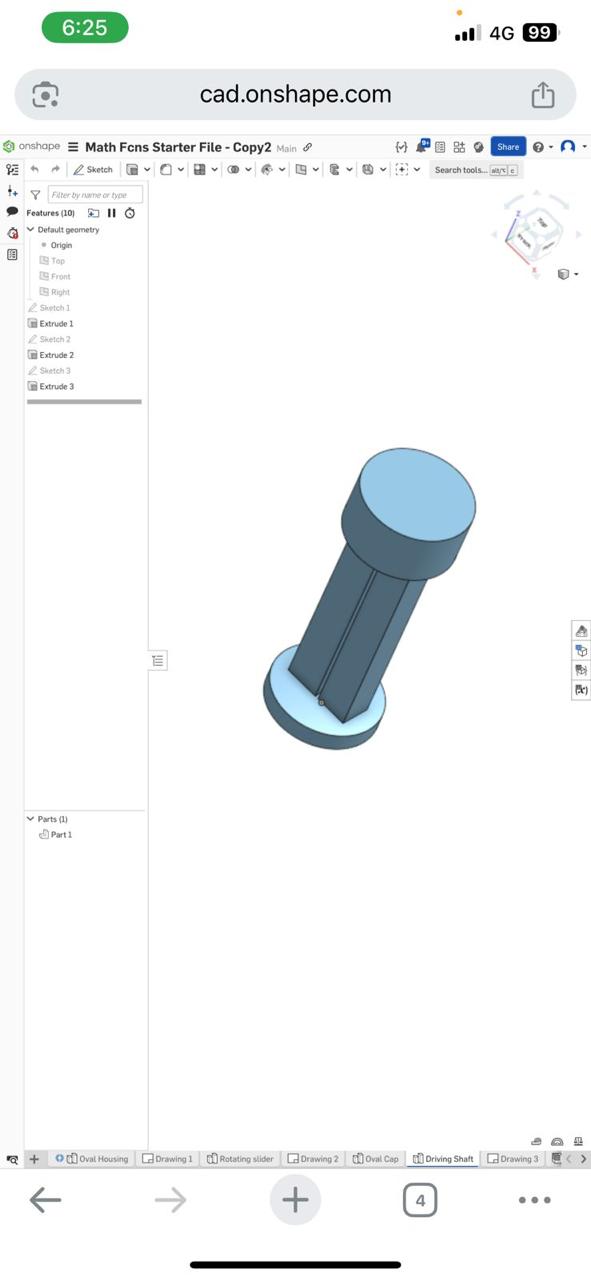

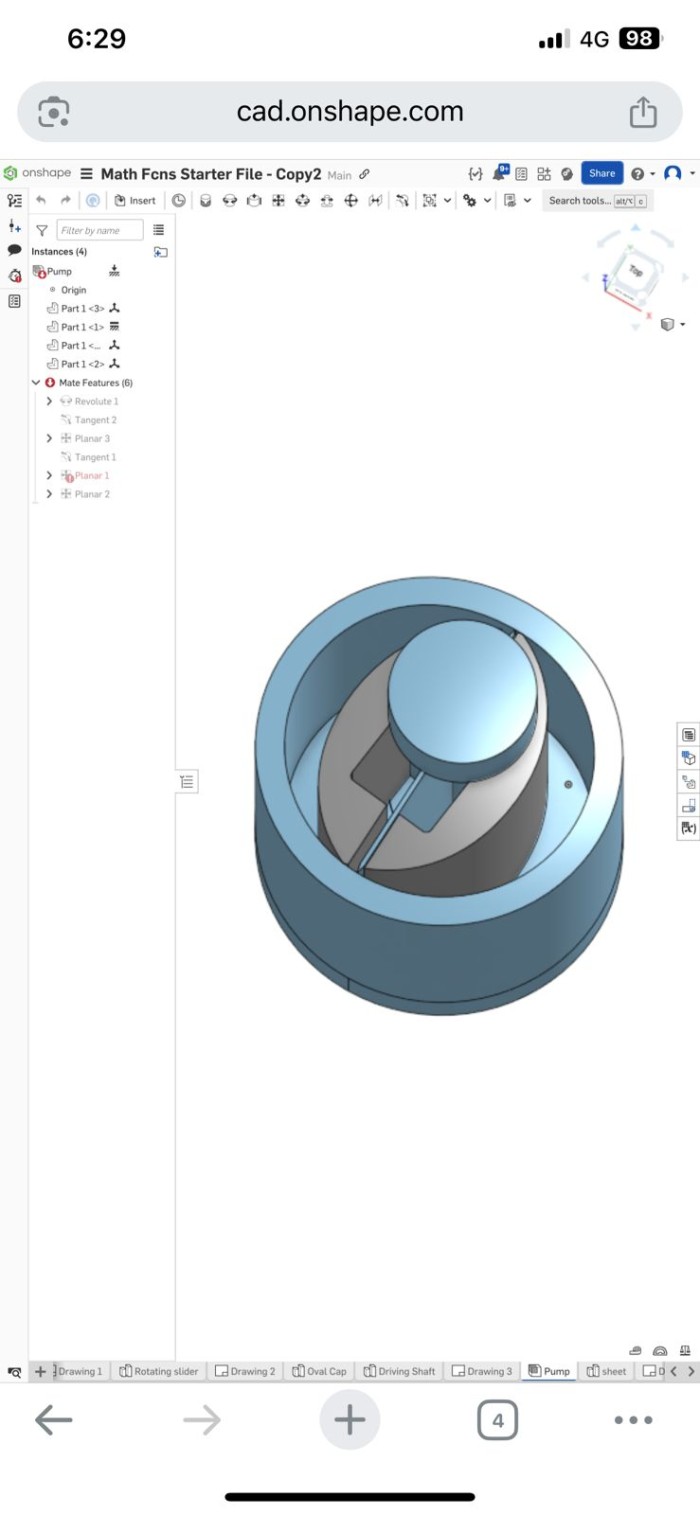

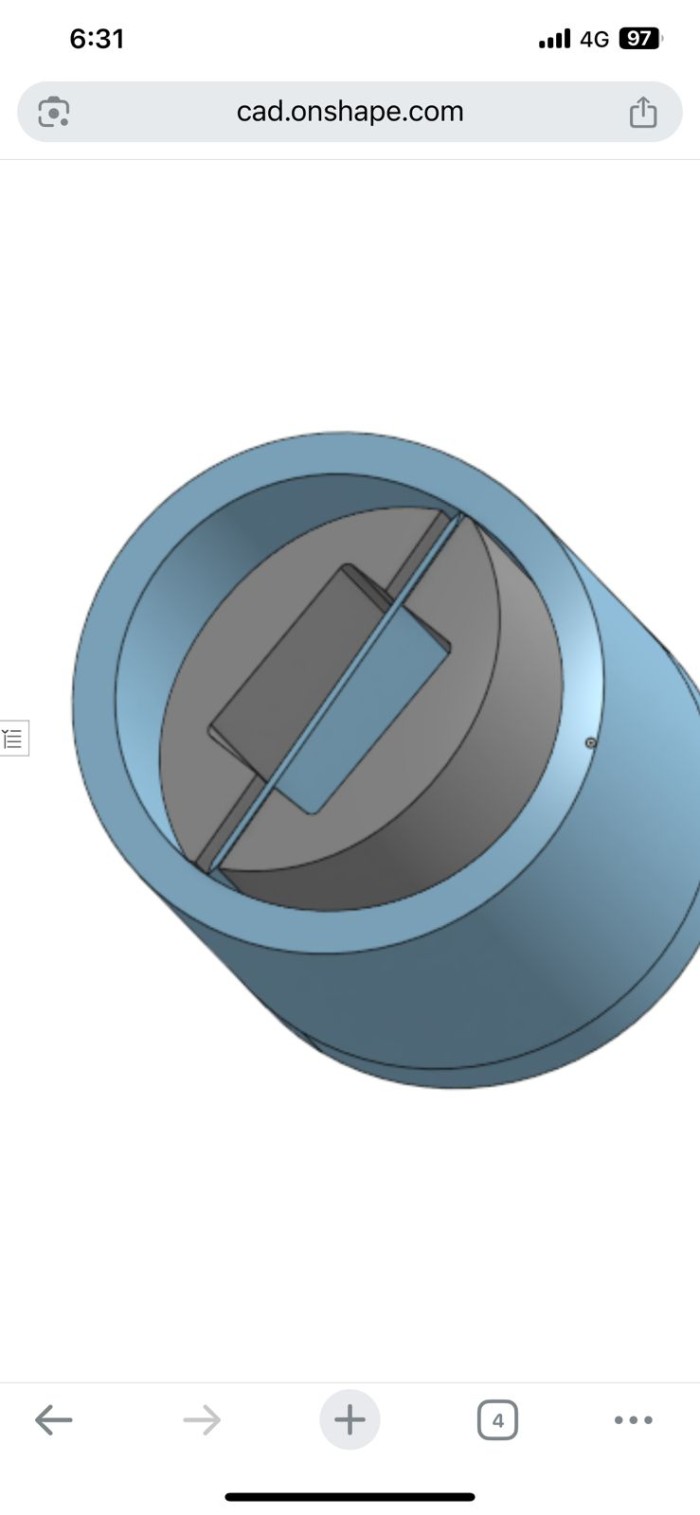

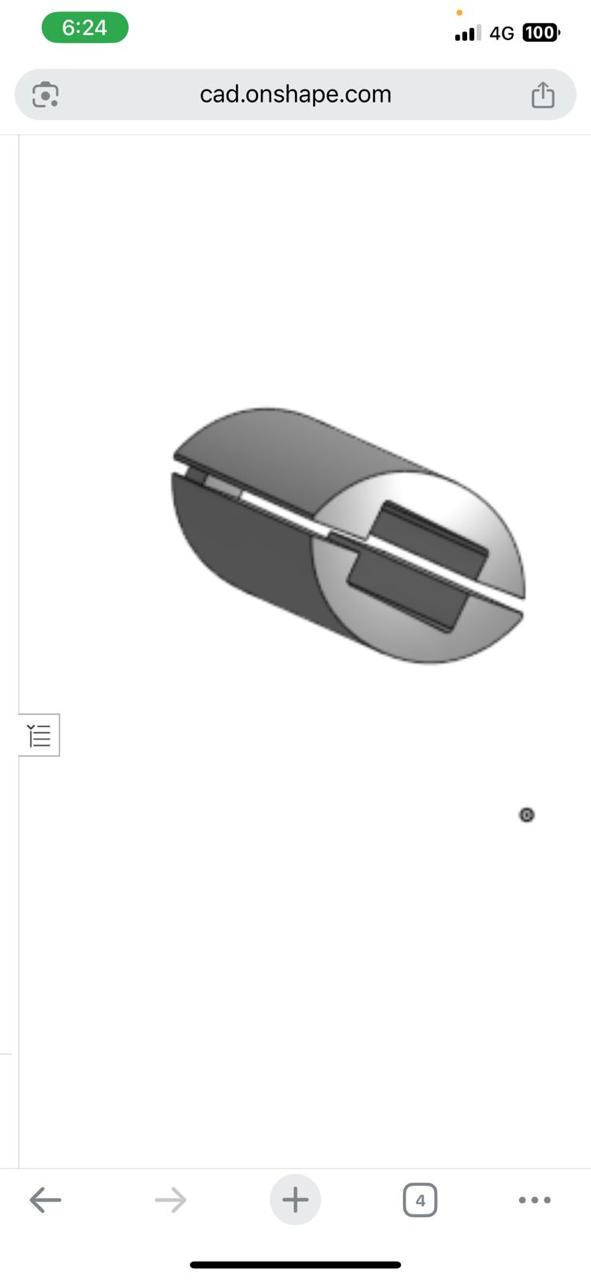

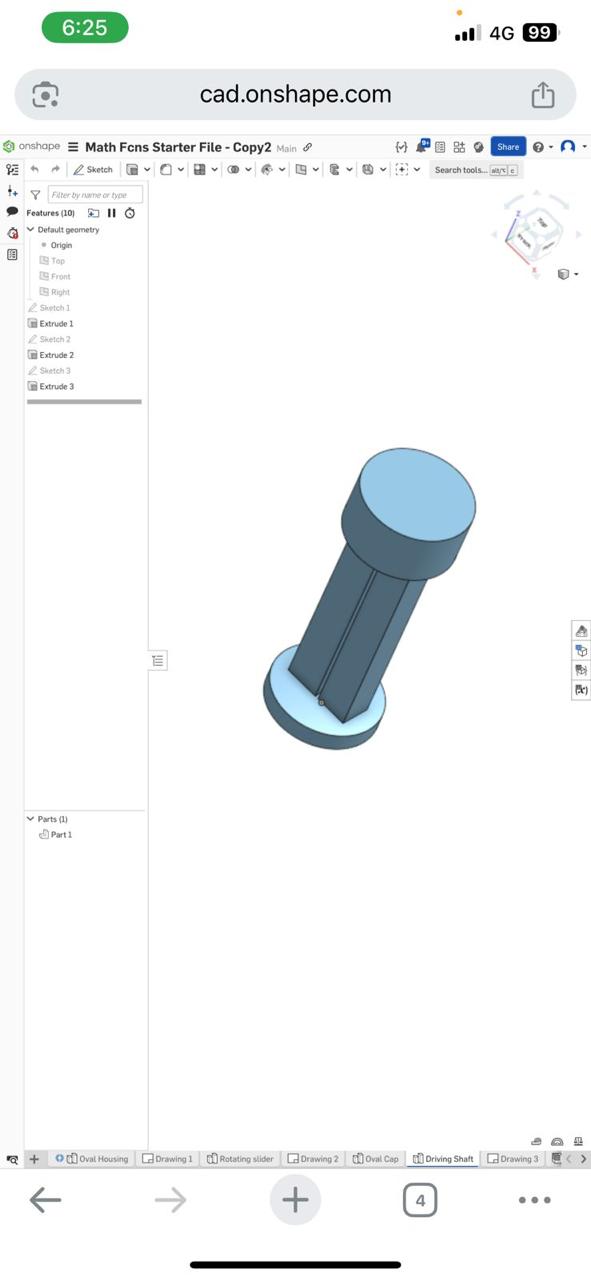

AN ASSEMBLY FOR GENERATING ROTARY LINEAR RECIPROCATING MOTION

[Category : - Automotive Accessories - DESIGN PATENTS- Pumps]

[Viewed 611 times]

Can be checked in the link below.rnrnStep 1:? Click on the below link or type Indian Patent Status on google and click on IPIndia services official link rnrn

Link rnrnStep 2: Click on “Patents” under the section 'Status'. rnrnStep 3: Click on “Application Status” in Patent Search Database.? rnrnStep 4: Enter Application Number “202511032825” and captcha code.? rnrnStep 5: Click on “Show Status” rnrnrnUNDrn[0002] A slider-crank mechanism is a mechanical system designed to convert rotary motion into linear motion or vice versa. It is a four-bar linkage consisting of a crank, a slider, and a connecting rod. This mechanism is one of the most widely used in pumps and internal combustion engines. However, it comes with several challenges. One significant drawback is the presence of numerous moving parts, which increases the complexity and requires additional maintenance. In engines, multiple cylinders are required to balance power stroke fluctuations, adding further challenges. Additionally, unwanted friction and noise are common, reducing overall efficiency. Vibrations also shorten the lifespan of components and machinery. To address these issues, extra measures such as balancing, lubrication, and other remedies are necessary, which in turn raises the overall cost of the machinery.rn[0003] However, there are some alternative designs, such as conventional rotary engines and positive displacement pumps like Wankel engines, gear pumps, and vane pumps, that offer some solutions but come with a few limitations. One major concern with the alternative design is ensuring proper sealing of the chamber. During compression or expansion, fluid may leak from one side to another due to imperfect seals at the tips of rotors or vanes. Furthermore, the alternative designs are inherently complex, involving internal gears and springs to control the motion of parts, which makes them less cost-effective and less practical. Additionally, lubricating the tips of vanes or rotors is inefficient, as these components come into direct contact with the working fluid, leading to high lubricant consumption. Rotary engine designs also feature narrow combustion chambers, which increase the surface area-to-volume ratio, resulting in greater heat loss and reduced efficiency.rn[0004] Hence, there is a need for an assembly for generating rotary linear reciprocating motion and a method thereof which addresses the aforementioned issue(s).rnOBJECTIVES OF THE INVENTIONrn[0005] The primary objective of the invention is to develop an assembly for generating rotary linear reciprocating motion with fewer moving parts, reducing complexity and maintenance. rnAnother objective of the invention is to provide a mechanism that generates the rotary linear reciprocating motion with fewer moving parts, primarily for use in rotary engines and rotary positive displacement pumps.rn

Patent publications:No publication

Patent publications:No publication

Asking price:

Make an offer

[ Home

| List a patent

| Manage your account

| F.A.Q.|Terms of use

| Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-12-13 23:12:02, Patent Auction Time.

Patent publications:

Patent publications:

Great invention

Great invention