Home List your patent My account Help Support us

Method of unrolling elastic material to napkin production

[Category : - MECHANICAL ENGINEERING- Baby products]

[Viewed 4284 times]

The method consists in application of the rule of unrolling elastic material elastic (lycra, spandex, etc.) from immovable, for example, conic shaped rollers in the industry of expendable baby napkin production. Immovable material with approachable endings enables inclusion of that material and bonding thereof in the course of a production line, so production process interruption is avoided and no costs related thereto are incurred. Currently, material rollers are movable and the process of bonding consists in interruption of a production process and in replacement of empty rollers with new ones on which material is rolled.

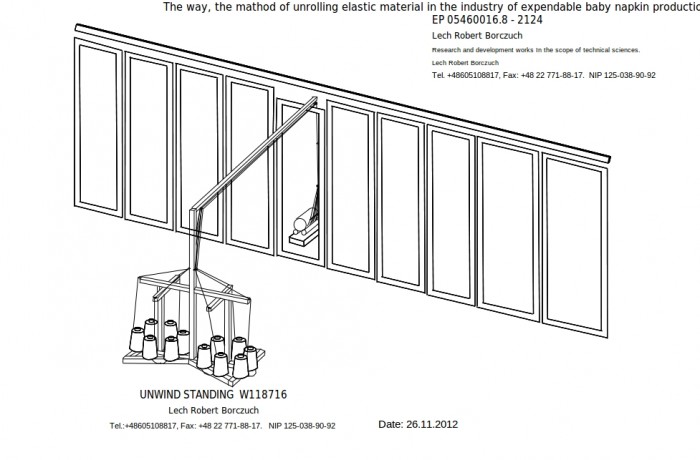

The second picture shows the method of unrolling EP05460016 (EU) using a unwinding stand W118716 (PL), PL66923.

Delivering method of elastic material focuses on reducing the cost of the product unit.

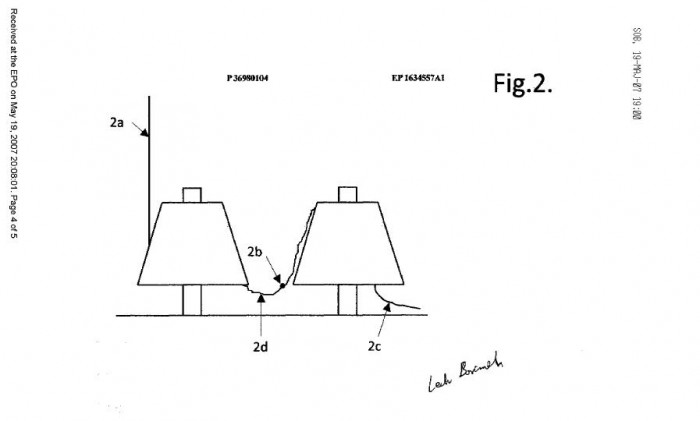

The presented figure shows:

1. Elastic spandex material – 280D to 1120D, in the form of thread-wound on the cylindrical or

conical rollers. The raw material may be supplied by many manufacturers, but it should have the

both ends of the material, approachable on the reel (2d,2c) to make connection (2b).

2. The unwinding stand of elastic material – according to the design W118716, made from aluminum profiles, meeting the standards of DIN EN 12020-2.

The Advantages of the method of unrolling EP05460016 using unwinding stand:

- The mechanical design of the line remains unchanged

- Constant tension rubber bands, which meets the requirements of quality and process

- It does not require electrical power and storage of spare parts

- Round holes prevent material falling or tangling thread

- Possible rupture of the material do not cause run away the material after the unwinder. Material is easy to threading and connecting without the extended stoppage.

- Low price, ease of installation, reliability and significantly reduce the cost of stoppages and

discarded diapers

- Depreciation period of equipment and installation costs is about 6 months

In case of conical bobbins, material should be stable unwound without rupture to the speed of

3000 pads per minute.

Mounting and utilization.

Mounting of unwinding stand needs the adaptive elements for production line – brackets and guides to

delivering the free material to unwinder and the line conveyor. Often this is a separation guide for threads

before unwinder and an separating roll at unwinder. Due to various types of production

lines and used unwinders, these elements must be designed individually.

Financial information

Offer of the sale of the EU patent Application, the cooperation with the companies that intend to implement the solution as well as transmittal of patent application into company assets in base of written contract.

Accounted Initial Value of Application: 11270 EUR.

Contact:

Eng. Lech Robert Borczuch

E-mail: [Use the button below to contact me]

Asking price:

Make an offer

Make an offer

[ Home | List a patent | Manage your account | F.A.Q.|Terms of use | Contact us]

Copyright PatentAuction.com 2004-2017

Page created at 2025-11-28 17:35:56, Patent Auction Time.

Patent publications:

Patent publications: EP 05460016

EP 05460016 PL 66923

PL 66923 Great invention

Great invention